More stable corn silage with Shredlage

Harvesting and ensiling maize according to the Shredlage technique leads to a different silage stability and feed value than the conventional chopping method. This is shown by research by Eurofins Agro. With the new chopping technique it is possible to chop corn in longer parts and still crack the grains properly.

In 2017 Eurofins Agro followed the development of the feed value of maize silages at 22 companies. 11 of these were well-preserved Shredlage pits, the other 11 were pits with conventionally chopped silage maize. The companies had a similar silage quality.

Bypass starch

The 2016 silages all contained a lot of dry matter and starch. At the first sampling in October / November, the Shredlage pits contained significantly less bypass starch and more ammonia than the traditionally ensiled maize. This indicates that the Shredlage method increases the rumen availability of starch directly after harvest. Starch, when readily available, is easily absorbed by bacteria. Consequently in Shredlage pits many fermentation processes take place in a short time. The main reason for this is the good grain cracking in the choppers equipped for Shredlage.

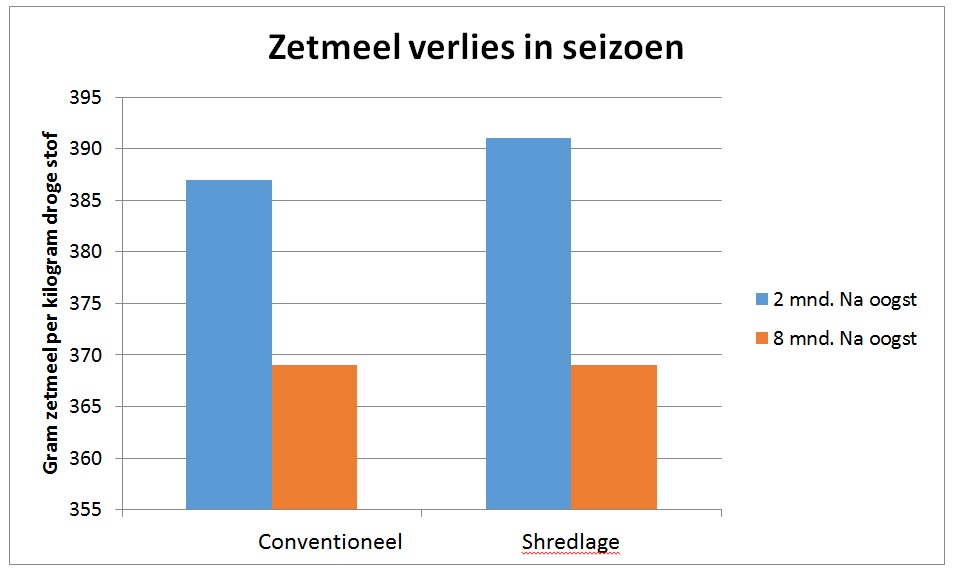

During storage, the amount of total starch and bypass starch decreases with both harvesting methods (see Figures 1 and 2). After four months in the pit, a difference between the two types of silage becomes visible. The amount of bypass starch in the Shredlage pits remains more stable than in the traditionally chopped silage maize.

Figure 1. Changes in silage composition during storage

Figure 2. Development of bypass starch; traditional versus Shredlage

Presumption is that this difference is caused by the difference in chop length: Shredlage silage has longer particles (> 15 mm) than conventionally harvested maize silage (8-10 mm). Coarser particles are probably fermented slower in the pit.

Immediately after ensiling Shredlage has much available energy for bacteria, hence a lot of preservation processes in a short time. This leads briefly to less bypass starch and more ammonia. The conversion of cell walls is slower, as chopping coarser means less surface area, requiring more effort of the bacteria. Eurofins Agro expects that this contributes to the stability of the pit.

Conclusion

Bypass starch behaves different in Shredlage silage than in conventionally harvested silage maize silage. Immediately after harvest, the bypass starch content of Shredlage pits is lower because the maize kernels are intensively cracked. The quantity of bypass starch in the silage remains stable for a longer period (up to six months) in Shredlage-silage than in traditionally ensiled silage maize. This can be of interest to keep milk production up to standard.